ERP Procurement Advisory Services

ERP implementations involve many functional teams, but Procurement is uniquely exposed. It touches the entire business and all suppliers, carries financial and compliance oversight, and often operates in ways that vary across departments, categories, and purchasing scenarios.

System integrators bring strong platform knowledge — and clients bring deep operational insight — yet both often approach the implementation from different angles. This gap can lead to a disconnect between what the system is designed to do and what procurement actually needs to achieve.

This is where Wolfe Procurement adds value: bridging the SI's system-led design with procurement's operational, strategic, and compliance needs.

We support organizations as the client-side P2P/S2P SME, ERP procurement advisor, and translator between the business and the system.

Two Sides, One Project — but Very Different Viewpoints

The System Integrator is feature-focused

System integrators bring strong platform knowledge and deep experience implementing ERP solutions. The resources leading the day-to-day design workshops are typically system configuration specialists, not procurement practitioners. Their role is to explain how the system works, guide configuration decisions, and deliver the platform according to methodology and scope.

This is appropriate for their role; however, it means the focus is on system capability, not on the operational realities of sourcing, contracting, supplier management, controls, approvals, or broader procurement strategy.

The client is operations-focused

Clients know how purchasing works today. Their priorities include:

- ensuring business continuity

- avoiding disruption

- protecting internal controls

- preserving familiar workflows

- minimizing user confusion

- maintaining approval structures

These perspectives create a natural gap in ERP projects

The SI is solving for system functionality. The client is solving for operational continuity.

This leaves critical questions unanswered:

This "middle space" is where ERP projects struggle — and where Wolfe Procurement provides clarity and direction.

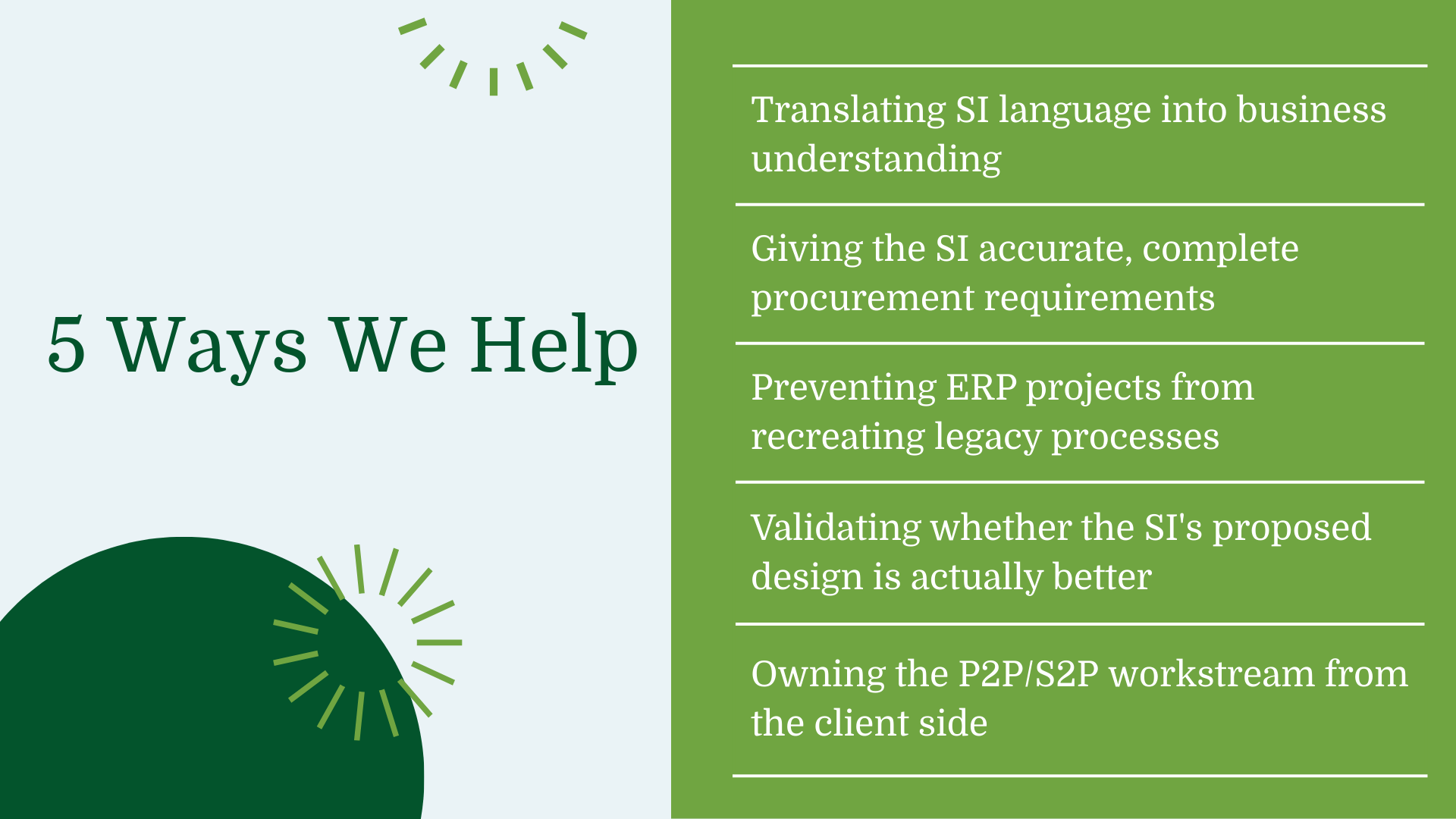

Our Role: The Bridge Between System Design and Business Reality

Wolfe Procurement sits in the middle of the SI and the client, ensuring the system reflects how procurement truly needs to operate — not just how the old system worked or how the SI describes functionality.

We act as the translator, advisor, and client-side P2P/S2P workstream lead.

Translating SI language into business understanding

When the SI explains how a process will work, client teams often wonder:

- "Is this actually better?"

- "Is this faster or slower?"

- "Does this simplify purchasing?"

- "Does this affect controls?"

- "Is this aligned to best practice?"

- "Will this create bottlenecks?"

We bridge the gap by translating technical design into:

- operational impact

- compliance implications

- end-user experience

- workload considerations

- procurement best practice

Clients gain clarity. The SI gains direction. The project gains alignment.

Giving the SI accurate, complete procurement requirements

Procurement is one of the most misunderstood areas in ERP projects because:

- processes vary widely across departments

- workflows often include many exceptions

- risk and controls differ by spend and category

- legacy systems have shaped habits and workarounds

- suppliers add external complexity

We provide the level of detail the SI needs, including:

- approval logic

- control points

- supplier onboarding requirements

- sourcing and contracting workflows

- P2P variations by spend and risk

- policy and governance constraints

- reporting and visibility needs

This ensures the SI builds the right solution — not just a solution.

Preventing ERP projects from recreating legacy processes

Without guidance, organizations often replicate the old system inside the new one.

Users naturally default to:

- "Our old system had this field."

- "We need the same approval path."

- "This step has always been there."

- "We can't change this."

We help organizations identify:

- which steps matter

- which steps slow the business down

- which approvals are excessive

- which controls align to risk

- which workflows can be simplified

- which data is actually needed going forward

This ensures the new ERP system is built intentionally, rather than historically.

Validating whether the SI's proposed design is actually better

This is one of the most overlooked elements in ERP projects.

The SI explains how the workflow functions. Wolfe Procurement evaluates whether it is an improvement.

We assess:

- efficiency gains

- user experience

- auditability

- control integrity

- reporting capability

- sourcing and contracting alignment

- supplier interaction

- long-term scalability

This protects the organization from inheriting the same challenges in a new platform.

Owning the P2P/S2P workstream from the client side

We serve as:

- SME

- translator

- advisor

- reviewer

- escalation point

- decision support

- quality control

- process interpreter

- SI liaison

This is a role clients rarely have the capacity or expertise to fill internally, and it is not the SI's responsibility to take on.

Why Procurement Needs This Role More Than Any Other Function

While every function benefits from strong leadership during an ERP project, procurement stands out because it's the intersection of operational complexity, supplier impact, financial controls, and audit risk.

Procurement stands out because it…

- touches every department

- affects all external suppliers

- drives spend control and financial risk

- carries high compliance and audit exposure

- includes processes that vary widely across the organization

- is shaped by both formal workflows and informal practices

- is often not well understood by system configuration specialists

A poorly designed procurement workflow can impact…

- spend visibility

- approval accuracy

- supplier onboarding

- contract compliance

- invoice matching

- payment timing

- risk management

- audit outcomes

- user adoption

- overall procurement effectiveness

ERP implementations succeed when system design and business reality are aligned — especially in procurement, where complexity, variability, and risk are highest.

Wolfe Procurement sits in the middle, helping clients understand what the SI is proposing, helping SIs get the clarity they need, and ensuring the organization implements the right procurement solution, not just a new one.

Need ERP Procurement Advisory Support?

If you are planning an ERP implementation or upgrade and want a partner that bridges the gap between your SI and your procurement function, we are here to help.

Andrew Wolfe

Founder & CEO | Wolfe Procurement